Note: Disable DC operation in CV 29 & set CV 11 to “0”, when using Stay/Keep Alives.

I have found with DC enabled (I always disable DC), the operation of the loco with no power (under Stay Alive), is very much reduced and the loco movement is jerky, using Soundtraxx Tsunami TSU-750/1000 & Econami steam decoders with Soundtraxx Current Keepers or TCS KA2s.

Train Control Systems (TCS), have two external Keep Alive modules and numerous decoders that include the Keep Alive, making stalling/hesitations a thing of the past. These are the:

KA1: Size L26.7 x W16.4 x H7.5 mm providing 3 – 6 seconds Stay Alive (TCS specification).

KA2: Size L33.0 x W11.6 x H8.8 mm providing 13 to 40 seconds Stay Alive (TCS specification).

Both the KA1 and KA2 are provided with 2 wires, where:

1. The BLUE wire is connected to the Function Common - DC Positive (Blue wire). For Tsunamis, this is NOT the RED Capacitor wire.

2. The BLACK with white trace wire, is connected to the DC Negative of the decoder.

Many decoders do not provide a DC Negative connection.

The “DC Negative” is easily found at the at the Anode ends of the two Input Diodes (Bridge Rectifier), that have their Cathodes (Band) Ends connected to the Track Input, more details shown below.

I have fitted KA2s to HO locos equipped with Soundtraxx Tsunami (TSU-1000, TSU-750 & AT-1000), Soundtraxx DSD100-LC etc, Loksound, TCS, NCE and other decoders (shown below), that provides between 5 and 60 seconds of stay alive, depending on Motor current draw etc.

The documentation says when connecting these units to TCS decoders, program the TCS decoder’s CV 182 to a value of 2.

When fitting the KA1/2s to other brands like Soundtraxx, there is no need to program CV 182.

See Bruce Patrarca aka Mr DCC, demonstrating the benefits of these Keep

Alives on his Club layout.

For more details and programming when using the KA1/2s, see the notes below the photos.

Connecting the TCS KA1/2s to Soundtraxx Tsunami Decoders.

1. Do NOT connect the KA1/2 BLUE wire to the RED wire to the Capacitor. If you do, the KA1/2 will only feed the Microprocessor and the sound portion of the Tsunami, while the sound will go on for 30 or so seconds, there will NOT be any stay alive to the Motor, causing it to stall/stop, immediately the loco experiences a power interruption (dirty track), explained in the schematics below.

2. I have found that if you remove the 220 uF Capacitor altogether, I could not read CVs of the Tsunamis on the Program Track. Replacing the 220 uF with a smaller 100 uF 16 Volt Electrolytic Capacitor, I was able to read CVs.

3. If you are having problems finding space for the 200 uF Capacitor in your loco installation, connect a 100 uF 16 Volt Capacitor, connected directly to the two pads (+ & -) of the AT-1000 Tsunami.

Installing the TCS KA1 or KA2 Modules.

Photos of my previous 4,700 uF Stay Alives are included with the Tsunami AT-1000, to show/explain on how to connect the Keep Alives.

Tsunami TSU-1000

- Blue wire to the Blue Function Common wire &

- Black with white trace wire, to the Black wire connecting the 220 uF Capacitor (not the Black Pick Up wire).

Tsunami TSU-750

- The Blue wire to the Blue Function Common wire &

- The Black/White trace wire to the Green/Yellow wire.

Tsunami AT-1000

- The Blue wire to the Blue Function Common Pad (Pads 2 or 9) &

- The Black/White trace wire to the Black wire connected to the 220 uF Capacitor (not the Black Pick Up wire) or to the Anodes of either of the 2 Diodes with the Cathodes (bands) ends connected to the Track Pick Up wires.

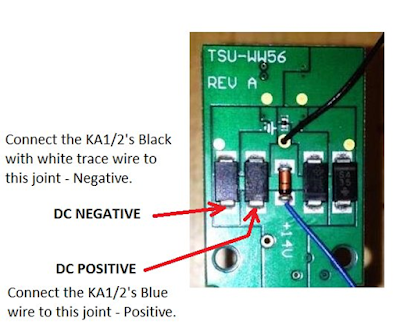

Shown below, the TCS KA2’s Black/White trace wire is connected to the Anode end of one of the Input Diodes & the Blue wire is connected to the Function Common on an AT-1000 decoder.

Tsunami GN-1000

The GN-1000 is different than other Tsunamis in that they have:

- An On Board 1.5 Volt Regulator for 1.5 Incandescent lamps. Do NOT connect to Tabs 2 and 11 like that on the AT-1000.

- The “+14 Volt” Pad near the Input Diodes is isolated from the Motor. If you use this connection there will be NO stay alive for the Motor.

Connect the TCS KA1/2 Stay Alive’s wires:

- Blue: to the Cathode (Band) end of the Track Input Diode adjacent to Tab 11.

- Black with White trace: to the Anode (NOT the band/stripe) end of the Track Input Diode adjacent to Tab 12 as shown below.

Above schematic is courtesy of Ulrich Models.

Econami 21 Pin

The “Pin Out” details of the ECO 21 Pin can be found at Bryan Vinaco’s SBS4DCC Web site at:

http://www.sbs4dcc.com/tutorialstipstricks/21mtcconnector.html

For the ECO 21 Pin, I connected the Keep/Stay Alive’s to the Loco’s Circuit Board (motherboard)and NOT to the 21 Pin decoder, as:

- Blue - Positive: to the Function Common (BLUE) to the Loco Lights etc or to Pin 16 (not shown in the below photo).

- Black/White trace – NEGATIVE: to Pin 20 as shown in the below photo.

Alternatively, the Stay/Keep Alives could be connected to the Input Diodes, see below under the heading of “To find the DC Negative of ANY decoder not shown above”

Soundtraxx in Bachmann, Intermountain & Proto.

The photo below shows the Stay Alive connections for a Soundtraxx equipped Bachmann RS-3 with the TSU-WW56 Circuit Board. Marty C suggested that Intermountain & Proto locos are the same.

QSI Revolution A.

NOTE: The Revolution A has a 5.0 Volt regulator & a 220 Ohm resistors included on the Board for LEDs or 1.5 Volt Incandescent Lamps. You CANNOT connect the TCS KA1/2’s BLUE wire to this 5.0 Volt Tab.

Connect the TCS KA1/2 as explained below and shown above.

- The Blue wire to “other” (Cathode) end of the Diode with the Anode (no stripe) that’s connected to either Track Pick Up.

- The Black/White trace wire to the “other” (Anode) end of the Diode with the Cathode end (stripe) that’s connected to either Track Pick Up.

QSI Revolution U

- Connect the BLUE wire to the BLUE decoder wire.

- Connect the BLACK/White trace wire to the Capacitor’s BLACK wire.

Loksound V3.5

See Streamlined Back shop 4 DCC web site entry at:

SBS4DCC

- ESU LokSound 52400 V3.5 "Keep Alive"

Loksound V4.0

See the appropriate Manual.

Soundtraxx DSD100-LC

- Remove the heat shrink from the decoder by slicing down one edge with a Razor Blade etc.

- Connect the BLUE wire to the BLUE decoder wire.

- Connect the BLACK/White trace wire to the Anode as shown with the yellow wire.

- Re-install Heat Shrink.

Soundtraxx DSD-AT100LC

- Connect the BLUE wire to the Function Common Tab or to the positive connection as shown

- Connect the BLACK/White trace wire to Anode as shown below.

DSD-B280LC

- Connect the BLUE wire to the Function Common - Pin 7 or to the positive connection.

- Connect the BLACK/White trace wire to Negative connection at the Anode as shown below.

Soundtraxx DSD-LL110LC

- Connect BLUE wire to the Function Common (Pin 7) or to the positive connection as shown

- Connect the BLACK/White trace wire to Anode of the Diode as shown below.

Soundtraxx DSD150

- Peel back the shrink wrap from the 9 Pin Socket end, as shown.

- Connect the Blue wire to the decoder Function Common BLUE wire.

- Connect the Black wire to the Diode (Anode end), as shown below.

NON Sound Decoders.

TCS T1

- Connect the BLUE wire to the Function Common Blue wire

- Connect the BLACK/White trace wire to the Negative connection of the decoder’s Bridge Rectifier as shown with the Green wire.

TCS M1

Locate the large Light Brown Capacitor on the decoder that has the Blue Wire attached to one end as shown below.

Scrape away some of the decoder's plastic coating on the other end of the Capacitor. This end of the Capacitor is the Negative for the Stay Alive.

Solder a piece of wire as shown, being very careful not to heat up the Capacitor too much.

NCE D14SR- Connect the BLUE wire to the Function Common Blue wire

- Connect the BLACK/White trace wire to Diode/Capacitor junction, shown with Green wire.

To find the DC Negative of ANY decoder not shown above:

- On the decoder, locate the 4 Diodes (Black rectangular blocks) used to rectify the DCC from the track, generally on one end of the decoder where the wires from the track pick-ups are secured/soldered to the decoder.

- The ANODE ends of the two Diodes that have their Cathodes (Band) Ends connected to the Track Input, form the DC NEGATIVE.

- The TCS T1 has a Bridge Rectifier. Connect the Black wire to the Negative Pad of this Bridge Rectifier.

- Smaller N/Z Scale decoders like the TCS M1, have really small Diodes or with decoders that you cannot identify the Input Diodes, to locate the DC Negative:

a. With the decoder powered.

b. Connect the RED Lead of your Multimeter, to the decoder’s Function Common.

c. Probe with the BLACK lead of your Multimeter around a large (well compared to the rest of the components) Orange or Brown block (a Capacitor).

d. One end should be the DC Negative, like where the Green wire is connected on the NCE D14SR decoder, above.

5. Hopefully you’ll find the DC Negative.

Perceived issues when using Keep Alives.

If there is communication with a KA2 equipped loco, it WILL stop when commanded to. The loco will stop at the station, stop when switching loads, not end up in the Turntable Pit etc.

But

Locos will keep running when an un-powered block is encountered like when using signals etc. You have to take this into consideration if you are using a Keep Alive.

Using Service mode of programming (the Program Track) may be difficult, see next.

Programming with KA1/2s.

I have found that programming a decoder (Tsunami) with a KA2 installed, on the Program Track using a Soundtraxx PTB100 Booster with my NCE Power Pro unit, there are instances when reading CVs, returns a value of 255 for the CV.

The theory to read CVs, is that the Command Station instructs the decoder to pulse the Motor according to the stored CV value. From these pulses of current from the C/S, the value is displayed. The only problem is a charged up KA2 or the Command Station may supply the pulses of current. If it is the KA2 supplying the power and not the Command Station, then there will be no pulses of current from the Command Station pulses to interpret to display the CV value, hence the 255 display.

In practice on the Program Track, if you get a 255, then try again with a discharged KA2 and try again. If you still get a 255 read, then you have to disconnect the KA2. I get successful reads of CV about 80-90% of the time.

Except for the initial read of a decoder after installation or troubleshooting why a decoder does not work, I use “On the Main – POM” mode of programming using Decoder Pro, where there is no issue.

More details of the Stay/Keep Alives.

Relative sizes of the Stay Alives I have used from Top L/H Counter clockwise.

TCS KAT14T1. T1 Motor only decoder including KA1 Keep Alive components.

TCS KA1 Shrink wrap removed showing 6 x 0.22 F 2.5 Volt Capacitors.

Lenz Power 1 Module (USP). 1 x 1.0 Farad 2.7 Volt Capacitor.

TCS KA2 Shrink wrap removed showing 5 x 1.0 Farad 2.7 Volt Capacitors.

4,700 uF 16V Electrolytic Capacitor as per my previous Stay Alive.

I have been using SIMPLE Stay/Keep Alive for years.

This comprised of the largest value capacitor I could fit into a HO loco, namely a 4,700 microfarad 16 Volt Electrolytic capacitor, a 100 Ohm resistor to limit the charging Inrush Current and a 1.0 Amp Diode to bypass the resistor, when the Capacitor discharges (supplying Stay Alive).

Components have become smaller. You can now purchase for less than a dollar, a 1.0 Farad 2.7 Volt Super Capacitors in 10 mm x 6.3 mm package.

To use the 2.7 Volt 1.0 Farad super capacitor in our 12.0 volt models:

Electronics can be are used to convert this low voltage energy into what the model needs, as Lenz has done with the USP, see below.

Or

Connect the 5 or 6 Capacitors in SERIES as to what we and TCS have done.

The electronics that Lenz has used with the Power 1/2 modules (USPs) does some extra things but can only be used with a Lenz Gold or QSI Titan decoder due to an extra Charge wire/connection is necessary. I have a YouTube video demonstrating that the decoder responds to commands (direction change etc), while running on Stay Alive power.

The TCS KA1 uses 6 x 220,000 uF 2.5 Volt Capacitors, while the KA2 uses 5 X 1.0 Farad 2.7 Volt Capacitors.

When connecting Capacitors in SERIES, using similar value Capacitors the effective capacitance Ct = C/n and the operating voltage of the package = 2.7 x n. Volts, providing an effective capacitance and operating voltage of, for the:

KA1: 36,667 uF (microfarads) at 15.0 Volts.

KA2: 200,000 uF (microfarads) at 13.5 Volts.

Apart from the 5/6 Capacitors of the KA1/2 there is a Diode and a 150 Ohm resistor, making what I call, a simple Stay Alive, the same as my 4,700 uF Stay Alive BUT with amazing differences. Comparing the 4,700 uF Stay Alive, the KA1 at 36,667 uF is has 7.8 times more stay alive energy and the KA2 at 200,000 uF has 42 times more providing much more stay alive than the quarter of a second, the 4,700 uF unit does, for a similar size package. Now it can be seen why these Keep Alives from TCS are so good.

But the best thing yet, the KA1 and KA2 can be used with ANY decoder.

Lenz Power 1 Module (USP) can ONLY be used on decoders that support USP, like the Lenz Gold and the QSI Titan. The energy stored at 2.7 Volts on the 1.0 Farad Capacitor has to made into a voltage that is suitable for a 12 Volt Motor, by some electronics comprising of what I can see, a small Coil, 2 x 6 Pin ICs, an 8 Pin IC, a Diode a Transistor/FET and numerous other components, provide the stay alive power. The high impedance input of the Gold decoder allows packet information, changes in direction, speed etc to get through to the decoder while running on stay alive (dead track) as evidenced on the Gold/USP YouTube video

Some years ago a modeller friend asked me to install Lenz decoders into his Bemo HOn3 fleet of locos. One unit a 4 wheel Tractor/Shunter was a real problematic runner, continually stalling/stopping in the Yard on his Exhibition layout. I installed a Lenz Gold/USB combination, resulting in smooth running through the Yard. He was ecstatic. This installation was a real challenge, fitting in the Gold plus USP into the small Cab but was worth it. I have since installed USPs into a few of his problem runners with similar great results.

Why do we need Stay/Keep Alive.

Dirt has been the enemy of model railroaders since we used electricity to operate locos. We have been able to put up with it, what has changed.

The introduction of SOUND locos.

Many modellers are building their dream layout in un-sealed environments where the air quality is not as clean as I would like it to be.

When a NON Sound loco experiences a power interruption from dirty track, gaps at turnout frogs etc, there would be a slight hesitation that in many cases would go un-noticed but with SOUND locos, you hear this hesitation with the sound disappearing them coming back on as the processor in the decoder stopped and started up again. This becomes quite annoying. Track cleaning isn’t the model railroader’s favourite chore, so I would persevere until it became unbearable. Applying CRC 2-26 to my track has helped immensely with reducing these sound reset interruptions.

Locos without flywheels and that is more than half of my steam locos, would most probably stop at these power interruptions, making this inconvenience a real hassle now.

On top of dirty track/wheels there are plenty of other things that contribute to a loss (interruptions), like:

- Track geometry/alignment.

- Gaps/Insulation at Points/Turnouts Crossings etc. Many chose Peco Electrofrogs or similar to reduce the unpowered area around the Frog.

- Locos with small numbers of wheels and pick-ups, no Tender Pick-ups etc.

- Brass, Brass/White Metal DJH Kits etc where one side Drivers/One Bogie picked up positive and Tender/ other Bogie picked up the negative.

- Poor contact at Drawbar and the Bogie Bolster.

- The material wheels are made from can have an effect on pick up. Some materials are better than others and I am not into replacing them.

- While the weight of a loco may be enough, due to where it is located, the loco may be un-balanced effecting traction and pick up, especially when over Points/Turnouts etc.

- Tender Pick-ups seem to be unreliable (example C32 and C35).

Rectifying some of these issues is possible but some are way out of league of many modellers and fitting a Keep Alive will hide these issues and result is better running.

Fitting Keep Alives does not mean you can eliminate track/rolling stock maintenance.

My NSW 4-6-4 C30 Tank Steam loco Keep Alive Installation.

As soon as I was able to get the TCS KA2, I installed it in one of my most problematic locos, a NSW 4-6-4 C30 Tank Steam loco.

During an operating session on my layout, this loco is scheduled to run the local Toronto Passenger from Fassifern to Newcastle and back again, a total run of about 150 feet but through two Peco Insulfrog Double Slip Points, twice and many Points/Turnouts. The C30 regularly stalls and I could not install a 4.700 uF Capacitor plus a TSU-750/Speaker. This loco was in desperate need of a TCS KA2.

I moved the Motor forward by about 5 mms to get the Motor out of the Coal Bunker area and modified a KA2 by cutting it in two sections, 3 Capacitors on one side & 2 Capacitors on the other side with both sections wired together, see photo above.

As I add ballast to my layout, I'm making my Points/Turnouts more reliable by linking the adjacent Point and Stock Rails as shown by the Wiring for DCC site but I am leaving the 45 -50 mm Frogs, DEAD (i.e. un-powered) and this loco negotiates them easily.

I/we operate all the Lower Deck Points/Turnouts manually (by finger) on my layout as I/we follow the train around. The fitting of a KA2 into the troublesome short wheel based locos like the C30, Brass and Brass White metal locos, now saves me adding Tortoises, Switches etc to these Points/Turnout, saving me heaps of money and time that is so precious, now we are getting older.

For those that do not know what a HO 13 cm (5 Inches) long NSW C30 looks like, here it is equipped with a Soundtraxx Tsunami TSU-750, a MRC 20 mm Speaker with the back removed and secured to the Cab Roof and now with a cut in two KA2 under the Coal Load.

For more details on how the Tsunamis work and other details, see my first “alive” page archived thanks to Mark Roach, at:

http://wayback.archive.org/web/20120729061658/http://www.members.optusnet.com.au/mainnorth/alive.htm

Making Stay Alives.

The 1.0 Farad 2.7 Volt Capacitors can be purchased from Digikey at:

https://tinyurl.com/4xb7ddzm

You could also purchase the 2 Diodes & resistor but I bought these at my local Jaycar. I made up Stay Alive Kits.

Connecting

the 8 components for a Stay Alive can be in any shape/configuration needed to

fit the Stay Alive in the available space, so long as the connections are made

as per the Stay Alive Schematic.

The five 1.0 Farad 2.7 Volt Capacitors are connected in SERIES.

Capacitors

Leads:NEGATIVE is adjacent to WHITE STRIPE on the Case.

POSITIVE is the

LONGER Lead.

With the Capacitor’s

Negative Stripe on the Left.

Bend the

two Leads with an “Angle” as shown.

Place some Blu Tak on the edge of the Bench.Place all the pre-bent Capacitors with their Leads "pointing out" a little.

Make sure the Negative Lead of ALL the Capacitors, are on the same side.

For each "joint", place one Lead over the other

& solder the Leads as shown

Trim the Leads - Do NOT trim the outside two Leads.

Press the soldered connections into the space between the Capacitors.

On the OTHER side of the Capacitor Pack.

Place the 13.0 Volt Zener Diode with the Black Band to the POSITIVE end of the Capacitor Pack

Bend the two Capacitor Leads around the Zener Diode's Leads as shown & solder.

Connect the 100/150 Ohm Resistor & Diode in PARALLEL as shown & solder together.

The Silver Band of the Diode becomes the Stay Alive's POSITIVE Lead & connected the the Function Common (Blue Wire).

The OTHER end is connected to the Capacitor Pack's POSITIVE end as shown.

A few examples in my NSW Locos.

Eureka Models 50 Class with all the Capacitors in row down one side of the re-positioned QSI decoder.

Auscision 45. Capacitors

arranged into a two row “5 Pack”, to fit them in a shorter but wider

“position”.

Trainorama 48 Class

4 Caps are in two rows & the

fifth Cap is placed in the position where the Crew, “was”.

.JPG)

.JPG)